Do you worry you are not maximising your production time?

Mapex’s MES provides real-time monitoring of your factory and allows you to measure your Overall Equipment Efficiency (OEE) score.

To get the most out of your production line, it is important to ensure that your equipment is running efficiently and at the highest possible capacity with limited unplanned downtime and production breaks. This will save your business significant time and money.

In this post, we will cover OEE in detail and how you can measure your production line’s OEE score and improve your factory’s efficiency.

What is Overall Equipment Efficiency?

OEE is a crucial indicator for productivity improvement. It is used to measure the efficiency of machinery in a production line of a factor.

According to experts, it is a best practices metric that identifies the percentage of planned production time that is truly productive.

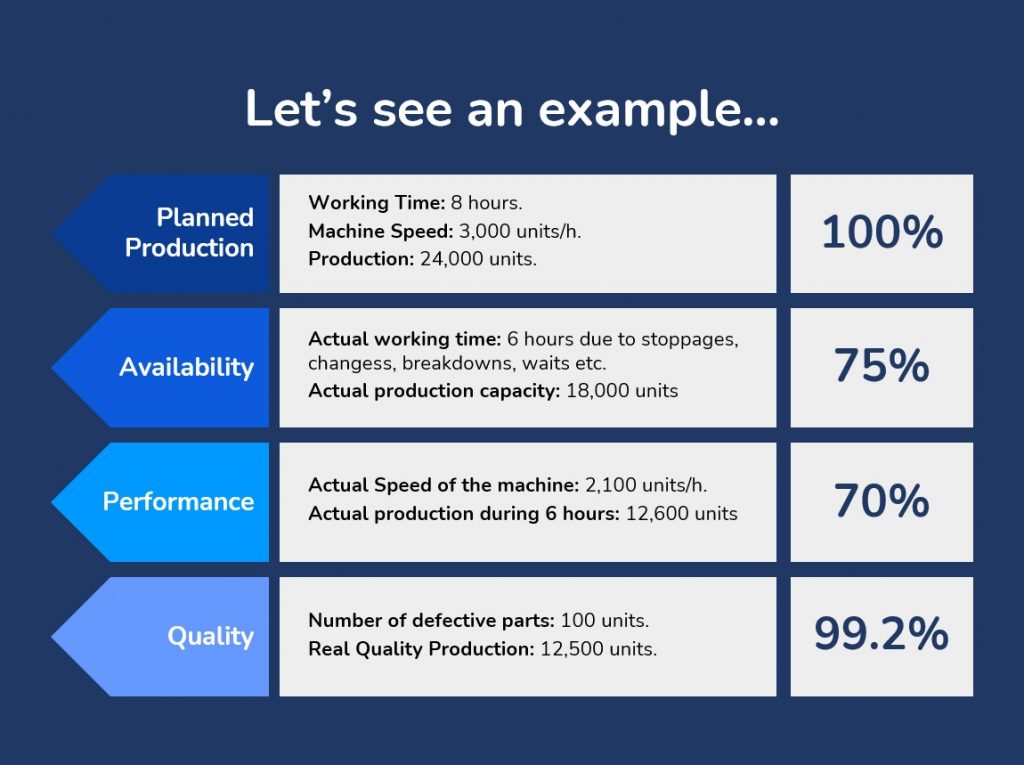

Knowing your OEE score is important as it can help you address three key factors of your production line: Availability, Performance, and Quality. Availability measures how long the machines are on standby. Performance measures whether the machines are running at the expected speeds. Lastly, Quality measures whether the outputs produced are in the right condition for the consumers to use.

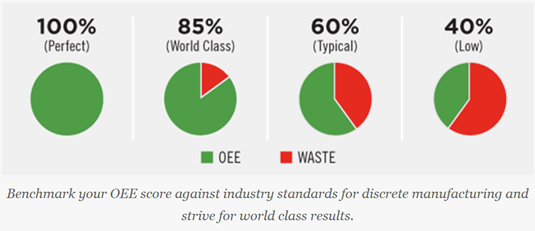

- OEE can be used both as a benchmark and as a baseline:

- As a benchmark, it can be used to compare the performance of your production line to industry standards or to test results for different shifts working on the same line.

- As a baseline it can be used to track progress over time in eliminating waste from your production line.

Your OEE score is calculated by measuring each of the three key factors: OEE = Availability x Performance x Quality.

Example:

OEE = 0.75 x 0.70 x 0.992

OEE = 52.08%

This production line has an OEE score of 52.08% which suggests it is inefficient in many areas as the OEE score has been reduced to half of the planned production.

Benefits of using Mapex production module to measure your OEE score

The Mapex Production Module:

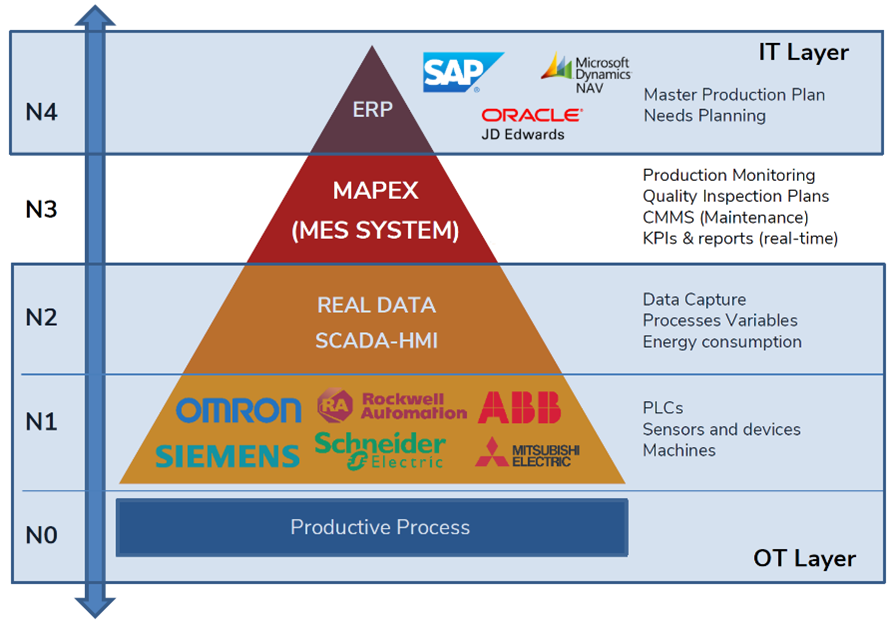

- Provides you with the ability to see and control everything in the factory in real time and to integrate this information in the ERP.

- Allows you to trace your products, batches, materials, and their functional appearance during the process.

- Is flexible and scalable to adapt to all factories, regardless of their size

- Helps make concrete improvements using real data to:

- increase availability of machines

- reduce inefficiencies and downtime to increase machine performance

- reduce inefficiencies in the production process to avoid defective products which improves quality and saves costs

- Offers increased reliability through accurate data and key indicators like OEE to improve and streamline decision making

With Mapex’s production module, you will be able to collect reliable real-time information to measure your factory’s OEE and make agile decisions to improve your production efficiency.

Book a MES Health Check with us to see how your OEE score compares to your peers and improve your factory’s OEE today!